WHO ARE WE?

We are the culmination of some 55 years experience in the manufacture of specialty formulated PVC protective linings, originally as the BFGoodrich Corporation and now as ProFusion Industries.

WHAT DO WE HAVE IN COMMON?

As was the case with BFGoodrich before us, we are the industry leader in the manufacture of high performance specialty formulated PVC protective linings. All of the manufacturing and technical know-how has been carried forward to ProFusion Industries. What’s more, all of the personnel, technical knowledge, talent, skills and equipment are now an integral part of our Protective Linings Division.

In fact, other than the name, our customers have detected no change. The technical support service and commitment to “best in the business” performance continues to be second to none and this along with expanded development and research will keep ProFusion Industries the leader in PVC protective linings.

A MEMBER OF THE PLASTIC FAMILY

Koroseal protective linings are specially compounded formulations with outstanding resistance to strong corrosive chemistry. Our linings thrive in applications where alternate materials fail. They are flexible and can be bonded to containment vessels in an infinite range of sizes and shapes. The material has excellent tear and abrasion resistance, and demonstrates outstanding chemical resistance properties.

Since this material is thermoplastic, it will soften at temperatures above 150° F. Operation at higher temperatures can be accomplished through the use of brick sheathing which affords both thermal and physical protection. Available in black and other colors subject to run size requirements.

As a general rule, Koroseal protective linings are not recommended for organic chemicals and solvents. Certain exceptions to these statements do exist; hence specific applications should be referred to ProFusion Industries for a recommendation through your applicator.

THE BUSINESS OF SPECIALIST CONTRACTORS APPLICATION

Lining performance can only be as good as the applicator who installs it. ProFusion Industries supplies Koroseal Protective Linings to a network of applicators throughout the USA and Canada, who provide installation services. They are staffed with highly skilled lining specialists and their plant equipment demonstrates versatility to handle practically any job.

The five basic steps in application are:

• Containment vessel cleaning and preparation

• Adhesive application

• Applying the lining

• Seaming

• Final inspection and testing

KOROSEAL PROTECTIVE LINING PRODUCTS

Product Features and Data Sheet

Product Features:

- Designed to provide containment vessel protection in harsh corrosive environments.

- Koroseal Linings are produced from proprietary compound formulations that offer superior protection and performance proven over more than 55 years of experience.

- Koroseal Protective Linings provide longer service life and the associated reduction in overall life cycle cost of ownership in comparison to alternative lining and coating application.

- Process and storage chemical vessels can be expected to provide improved reliability and up-time.

- Proprietary two-component adhesive system for bonded application has stood the test of time with regard to bond reliability, longevity and strength.

Data Sheet:

Physical Property |

Typical Performance |

Test Method |

| Hardness | 91 ≄ 5 | ASTM D-2240 |

| Tensile | 2500 psi | ASTM D- 412 |

| Ultimate Elongation | 250% | ASTM D-412 |

| Specific Gravity | 1.255 | ASTM D-792 |

| Color | Black | Visual |

Size (TxWxL) |

Color |

Approximate Weight

|

Warehouse Stock Product Number |

| 1/16” x 36” x 40 yds | Black | 152 lbs. | 39-14-0040-003 |

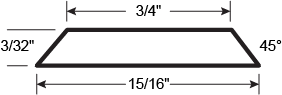

| 3/32” x 36” x 25 yds | Black | 140 lbs. | 39-14-0010-003 |

| 3/32” x 48” x 25 yds | Black | 187 lbs. | 27-14-5010-003 |

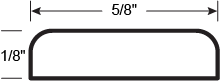

| 1/8” x 36” x 20 yds | Black | 151 lbs. | 39-14-0030-003 |

| 1/8” x 48” x 20 yds | Black | 201 lbs. | 27-14-5030-003 |

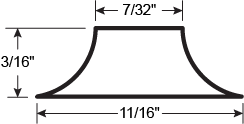

| 3/16” x 36” x 15 yds | Black | 170 lbs. | 39-14-0020-003 |

| 3/16” x 48” x 15 yds | Black | 231 lbs. | 27-14-5035-003 |

Product Features and Data Sheet

Product Features:

- Designed to provide enhanced protection and performance in the harshest corrosive environments.

- Specially suited for containment vessels utilized in both hard (industrial) and decorative chrome plating environments.

- Proprietary compound formulations that build upon the long-term success of standard Koroseal Linings with enhancements that result in significantly reduced plasticizer mobility and the associated extraction rates.

- Improved tolerance to process/chemistry anomalies that can cause periodic elevated temperature excursions.

- Infrequent process temperature excursions to 165℉ can be tolerated without causing measureable plasticizer migration and the resultant reduction in service life.

- Reduced plasticizer mobility results in longer service life and the associated reduction in overall life cycle cost of ownership.

- Process tank lines can be expected to provide improved reliability and up-time.

Data Sheet :

Physical Properties |

Typical Performance |

Test Method |

| Hardness | 91 ≄ 5 | ASTM D-2240 |

| Tensile | 2000 psi | ASTM D-412 |

| Ultimate Elongation | 200% | ASTM D-412 |

| Specific Gravity | 1.2353 | ASTM D-792 |

| Color | Black | Visual |

Size (TxWxL) |

Color |

Approximate Weight

|

Warehouse Stock Product Number |

| 1/8” x 48” x 20 yds | Black | 199 | 27-14-5040-963 |

| 3/16” x 48” x 15 yds | Black | 220 | 27-14-5050-963 |

| 3/16” x 36” x 15 yds | 27-14-5055-963 |

The High Performance Koroseal is intended for hard plating and higher temperature environments. Plasticizer extraction is limited when utilizing this lining that is designed for the harshest application.

Net Weight lbs/gal |

Warehouse Stock Product Number |

|

| Primer No. A-64-B | 7.2 | 75-15-0201-008 |

| Cement No. A-730-B | 7.2 | 75-15-0404-008 |